Renault BIW Project

Advanced Body in White engineering and structural optimization across next-generation platforms.

Comprehensive BIW engineering: structural analysis, optimization, and manufacturing support for Renault vehicle platforms.

15% weight reduction with 25% stiffness improvement and significant cost optimization through simulation-driven design.

12-engineer team over 18 months, delivering validated results aligned with Euro NCAP safety requirements.

Project Description

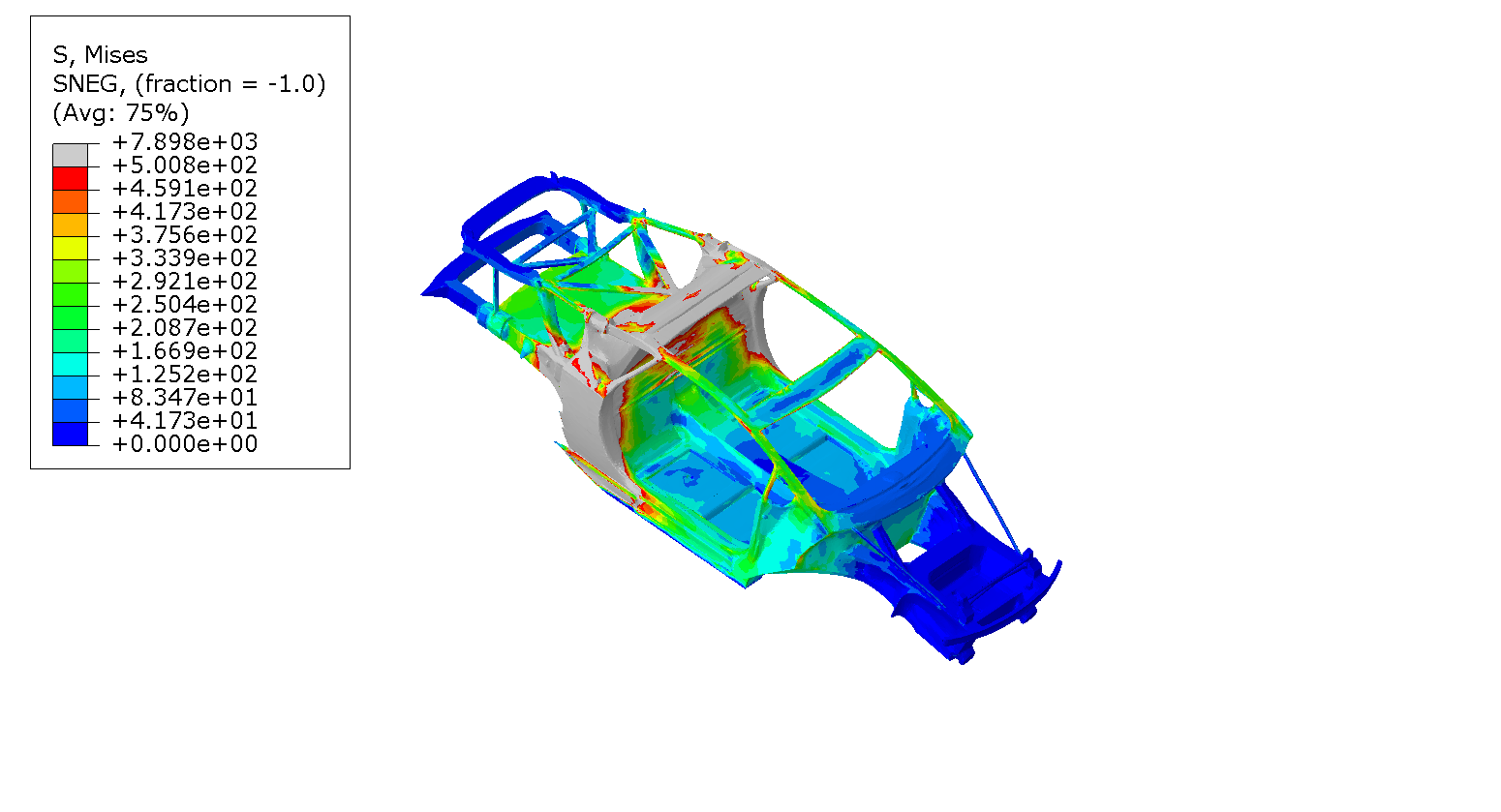

MecMaroc partnered with Renault to execute advanced finite element analysis (FEA) and optimization of BIW structures. The engagement focused on structural integrity, weight reduction, and manufacturing efficiency while maintaining the highest safety standards and correlation to test.

Project Objectives

- Meet performance & safety targets with margin

- Reduce mass while preserving stiffness/strength

- Accelerate development via simulation-led loops

- Ensure manufacturing feasibility & documentation

Technical Environment

- ANSYS Mechanical / Abaqus nonlinear & dynamic

- HyperMesh meshing & model preparation

- LS-DYNA crash simulation workflows

- CATIA V5/V6 for CAD & packaging

Technologies & Methodologies

Stress, modal, and vibration analysis

Energy absorption & intrusion limits

Damage, life, and hotspots

Feasibility, joining & process inputs

Project Results

Optimized material & topology

Targeted reinforcements

Materials & process improvements

Simulation vs. test